Home » Public Forums » GMCnet » How to make curved PVC valences

| How to make curved PVC valences [message #191533] |

Wed, 28 November 2012 17:43  |

kerry pinkerton

kerry pinkerton

Messages: 2565

Registered: July 2012

Location: Harvest, Al

Karma: 15

|

Senior Member |

|

|

Pretty simple really. Takes a table saw or jig saw, some sandpaper, a heat gun, a few scraps of wood, and a few C clamps or vice grips.

Photo album for the email folks is:http://www.gmcmhphotos.com/photos/how-to-make-curved-pvc-valences/p46624-r-0012.html

But the text is here:

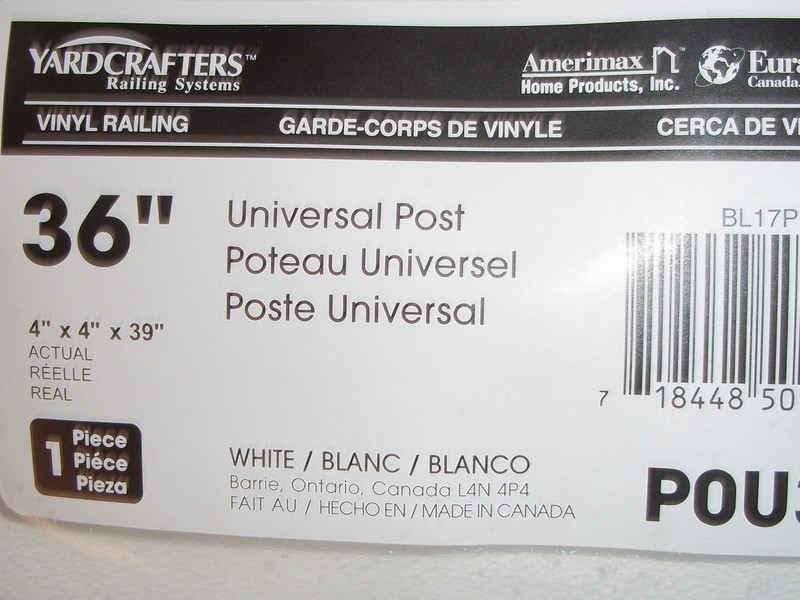

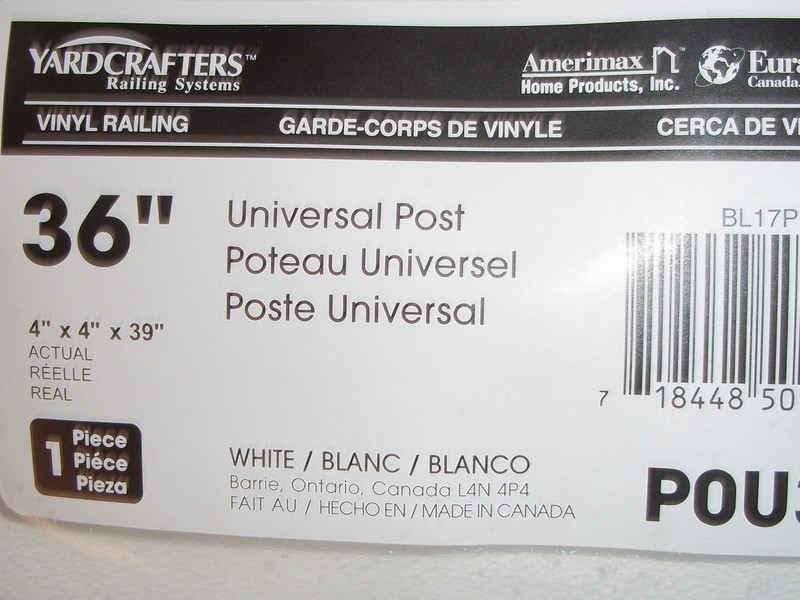

This is what I started with, a 36" piece of 4x4x1/8 vinyl from Lowes.

http://www.gmcmhphotos.com/photos/data/6237/R_0012.jpg

http://www.gmcmhphotos.com/photos/data/6237/R_0024.jpg

Then I marked the profile on a piece of 2x4. In retrospect I should have made the cut more in the middle...more on that later.

http://www.gmcmhphotos.com/photos/data/6237/R_0032.jpg

Just verifying the fit.

http://www.gmcmhphotos.com/photos/data/6237/R_0043.jpg

Cut the 4x4 into four 1 1/2 x1" angles on the table saw. You could use different sizes as necessary but this is what I used for my Micro Mini Blinds. If someone will tell me what kind of depth is needed for the day night shades, I'd appreciate it.

http://www.gmcmhphotos.com/photos/data/6237/R_0061.jpg

Clamp in place. It will twist and warp. Not to worry.

http://www.gmcmhphotos.com/photos/data/6237/R_0081.jpg

I used a Harbor Freight heat gun on high and as the PVC get hot it flattens out and stretches. Make sure it is down all over the curve and let it cool before you pull it off the form. Remember what I said about making the cut in the center of the board? If I had, I would have had a male and a female pattern and just pulled the two together as the PVC was heated. I'd do that on the next batch.

http://www.gmcmhphotos.com/photos/data/6237/R_0091.jpg

I cut a slot in a piece of plywood, cut a 1" strip of PVC, heated it, and once it bent, set a weight on it while it cooled.

http://www.gmcmhphotos.com/photos/data/6237/R_010.jpg

http://www.gmcmhphotos.com/photos/data/6237/R_011.jpg

Kerry Pinkerton - North Alabama

Had 5 over the years. Currently have a '06 Fleetwood Discovery 39L

|

|

|

|

| Re: How to make curved PVC valences [message #191534 is a reply to message #191533] |

Wed, 28 November 2012 17:44   |

kerry pinkerton

kerry pinkerton

Messages: 2565

Registered: July 2012

Location: Harvest, Al

Karma: 15

|

Senior Member |

|

|

Part two:

This is the angle I'll glue to the valence so you have something to screw to. Use plain old PVC glue. Works good, lasts a long time. Put the angles where you want them and make them as long or as short as you want.

http://www.gmcmhphotos.com/photos/data/6237/R_013.jpg

This batch I'm putting up temporarily on the side of my coach I haven't done yet. I just painted them with some plastic paint and will use the metal Ls that were holding the crappy wooden valences up.

http://www.gmcmhphotos.com/photos/data/6237/R_0141.jpg

That's it.

Yes, I will make some for sale if there is interest. Probably $20 a window for a 'kit'. Two each 36" long curved pieces and angles. You cut to length, glue on the tabs where you want them, and paint or upholster to your hearts desire.

Kerry Pinkerton - North Alabama

Had 5 over the years. Currently have a '06 Fleetwood Discovery 39L

[Updated on: Wed, 28 November 2012 17:44] Report message to a moderator |

|

|

|

| Re: How to make curved PVC valences [message #191538 is a reply to message #191534] |

Wed, 28 November 2012 17:55   |

rcjordan

Messages: 1913

Registered: October 2012

Location: Elizabeth City, North Car...

Karma: 1

|

Senior Member |

|

|

Nice looking job, Kerry. I expect you'll sell some sets.

SOLD 77 Royale Coachmen Side Dry Bath

76 Birchaven Coachmen Side Wet Bath

76 Eleganza

Elizabeth City, NC

|

|

|

|

| Re: [GMCnet] How to make curved PVC valences [message #191546 is a reply to message #191533] |

Wed, 28 November 2012 18:16   |

Ken Henderson

Ken Henderson

Messages: 8726

Registered: March 2004

Location: Americus, GA

Karma: 9

|

Senior Member |

|

|

Kerry,

Nice job; gonna make lots of folks envious.

Just a minor suggestion: It appears you've added mounting tabs top &

bottom. With the PVC, I'd suggest adding at least another tab half way up

because I suspect there's going to be a slight tendency for the PVC to

return to its original curvature when exposed to our summer heat.

Of course, that poses another problem: The blinds may tend to catch on the

tabs as they're raised & lowered. :-(

Now everyone knows why I have exposed mounting screws.

Ken H.

On Wed, Nov 28, 2012 at 6:43 PM, Kerry Pinkerton wrote:

>

>

> Pretty simple really. Takes a table saw or jig saw, some sandpaper, a

> heat gun, a few scraps of wood, and a few C clamps or vice grips.

>

> Photo album for the email folks is:

> http://www.gmcmhphotos.com/photos/how-to-make-curved-pvc-valences/p46624-r-0012.html

> ...

_______________________________________________

GMCnet mailing list

Unsubscribe or Change List Options:

http://temp.gmcnet.org/cgi-bin/mailman/listinfo/gmclist

Ken Henderson

Americus, GA

www.gmcwipersetc.com

Large Wiring Diagrams

76 X-Birchaven

76 X-Palm Beach

|

|

|

|

| Re: [GMCnet] How to make curved PVC valences [message #191547 is a reply to message #191533] |

Wed, 28 November 2012 18:17   |

werewilfs

werewilfs

Messages: 329

Registered: July 2012

Location: Rappahannock County, VA

Karma: 0

|

Senior Member |

|

|

Excellent! Thanks for this.

Jared

Amissville, VA

73 PD

________________________________

From: Kerry Pinkerton <Pinkertonk@MCHSI.com>

To: gmclist@temp.gmcnet.org

Sent: Wednesday, November 28, 2012 6:43 PM

Subject: [GMCnet] How to make curved PVC valences

Pretty simple really. Takes a table saw or jig saw, some sandpaper, a heat gun, a few scraps of wood, and a few C clamps or vice grips.

Photo album for the email folks is:http://www.gmcmhphotos.com/photos/how-to-make-curved-pvc-valences/p46624-r-0012.html

But the text is here:

This is what I started with, a 36" piece of 4x4x1/8 vinyl from Lowes.

http://www.gmcmhphotos.com/photos/data/6237/R_0012.jpg

http://www.gmcmhphotos.com/photos/data/6237/R_0024.jpg

Then I marked the profile on a piece of 2x4. In retrospect I should have made the cut more in the middle...more on that later.

http://www.gmcmhphotos.com/photos/data/6237/R_0032.jpg

Just verifying the fit.

http://www.gmcmhphotos.com/photos/data/6237/R_0043.jpg

Cut the 4x4 into four 1 1/2 x1" angles on the table saw. You could use different sizes as necessary but this is what I used for my Micro Mini Blinds. If someone will tell me what kind of depth is needed for the day night shades, I'd appreciate it.

http://www.gmcmhphotos.com/photos/data/6237/R_0061.jpg

Clamp in place. It will twist and warp. Not to worry.

http://www.gmcmhphotos.com/photos/data/6237/R_0081.jpg

I used a Harbor Freight heat gun on high and as the PVC get hot it flattens out and stretches. Make sure it is down all over the curve and let it cool before you pull it off the form. Remember what I said about making the cut in the center of the board? If I had, I would have had a male and a female pattern and just pulled the two together as the PVC was heated. I'd do that on the next batch.

http://www.gmcmhphotos.com/photos/data/6237/R_0091.jpg

I cut a slot in a piece of plywood, cut a 1" strip of PVC, heated it, and once it bent, set a weight on it while it cooled.

http://www.gmcmhphotos.com/photos/data/6237/R_010.jpg

http://www.gmcmhphotos.com/photos/data/6237/R_011.jpg

--

Kerry Pinkerton

North Alabama, near Huntsville,

77 Eleganza II, "The Lady", 403CI, also a 76 Eleganza being re-bodied as an Art Deco car hauler

_______________________________________________

GMCnet mailing list

Unsubscribe or Change List Options:

http://temp.gmcnet.org/cgi-bin/mailman/listinfo/gmclist

_______________________________________________

GMCnet mailing list

Unsubscribe or Change List Options:

http://temp.gmcnet.org/cgi-bin/mailman/listinfo/gmclist

Jared & Stefanie Kohl

Rappahannock County, VA

1973 Painted Desert "Onslow"

|

|

|

|

|

|

|

|

|

|

| Re: How to make curved PVC valences [message #191562 is a reply to message #191533] |

Wed, 28 November 2012 21:29   |

Dennis S

Dennis S

Messages: 3046

Registered: November 2005

Karma: 2

|

Senior Member |

|

|

Kerry,

Thank you for the great tutorial!

I am very impressed with the PVC valence look.

For those of us who want a bottom tray -- should not be difficult to adapt as well.

Regards,

Dennis

Dennis S

73 Painted Desert 230

Memphis TN Metro

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Re: How to make curved PVC valences [message #249309 is a reply to message #249308] |

Sat, 10 May 2014 08:53   |

kerry pinkerton

kerry pinkerton

Messages: 2565

Registered: July 2012

Location: Harvest, Al

Karma: 15

|

Senior Member |

|

|

djester wrote on Sat, 10 May 2014 08:30Are you still making these? Sure would like a set for five windows.

Dave

Not really Dave. The curved valences work fine for the small windows but on the larger ones, the blinds hang up because of the weight on them in the middle of the curve. You have to raise the blinds, adjust the angle, and lower them again. Not really very professional and for that reason I decided not to sell them.

They MIGHT work on the mid size windows (rear of coach). We haven't tried them there yet. They also might work better with other than the micro-mini blinds that we have. We're going to be changing to different blinds/shades and if the curved valences work better there, I'll start making them again.

Kerry Pinkerton - North Alabama

Had 5 over the years. Currently have a '06 Fleetwood Discovery 39L

|

|

|

|

| Re: How to make curved PVC valences [message #249310 is a reply to message #249309] |

Sat, 10 May 2014 09:12   |

djester

djester

Messages: 145

Registered: January 2014

Location: Indianapolis

Karma: 0

|

Senior Member |

|

|

Thanks, Kerry, sure wish someone would come up with a good DIY solution. Somewhere I saw that someone made them out of an "H" channel, or mullion, but can't find source for that kind of channel, or an explanation of how it was done.

Dave

David A. Jester

Indianapolis, In

1975 Palm Beach

djester@comcast.net

|

|

|

|

| Re: [GMCnet] How to make curved PVC valences [message #249311 is a reply to message #249309] |

Sat, 10 May 2014 09:15   |

|

USAussie

USAussie

Messages: 15912

Registered: July 2007

Location: Sydney, Australia

Karma: 6

|

Senior Member |

|

|

Dave,

There is this solution which GeneE up in Canada came up with:

http://www.gmcmhphotos.com/photos/aa-miscellaneous-photos/p32919-venetian-blind-valence.html

Regards,

Rob M.

Sydney, Australia

-----Original Message-----

From: Kerry Pinkerton

Not really Dave. The curved valences work fine for the small windows but on the larger ones, the blinds hang up because of the

weight on them in the middle of the curve. You have to raise the blinds, adjust the angle, and lower them again. Not really very

professional and for that reason I decided not to sell them.

They MIGHT work on the mid size windows (rear of coach). We haven't tried them there yet. They also might work better with other

than the micro-mini blinds that we have. We're going to be changing to different blinds/shades and if the curved valences work

better there, I'll start making them

--

Kerry

_______________________________________________

GMCnet mailing list

Unsubscribe or Change List Options:

http://temp.gmcnet.org/cgi-bin/mailman/listinfo/gmclist

Regards,

Rob M. (USAussie)

The Pedantic Mechanic

Sydney, Australia

'75 Avion - AUS - The Blue Streak TZE365V100428

'75 Avion - USA - Double Trouble TZE365V100426

|

|

|

|

| Re: [GMCnet] How to make curved PVC valences [message #249313 is a reply to message #249311] |

Sat, 10 May 2014 09:32   |

djester

djester

Messages: 145

Registered: January 2014

Location: Indianapolis

Karma: 0

|

Senior Member |

|

|

Very interesting solution, Rob. I'll have to think that through. Looks like one would have to take down cabinets to attach.

Dave

David A. Jester

Indianapolis, In

1975 Palm Beach

djester@comcast.net

|

|

|

|

|

|

|

|

Goto Forum:

Current Time: Fri Nov 15 23:06:55 CST 2024

Total time taken to generate the page: 0.01236 seconds

|

GMCforum

GMCforum